|

|

|

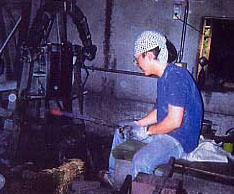

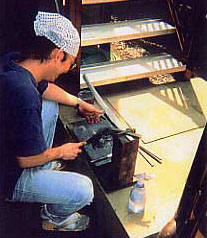

The Swordmaking Process |

|

|

|

you can see all this processes in Kozukakobou DVD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2.Crushing the tamahagane(Japanese steel) |

|

|

3.After the wafers of tamahagane are stacked onto the tekogane,they are heated and beaten togather. |

4.A cut is made across the steel,making it ready for folding. |

5.Preparing the kawagane(skin steel) |

|

|

1.Cutting the charcoal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6.Wrapping the kawahagane around the core steel(shingane).This is called Kobuse. |

|

| 7.Heating and hammering,fusing the Kobuse togather. |

|

|

|

| 8.Once all the joins are secure,the Kobuse is heated and hammered out into the shape of blade. |

|

9. Separating the blade from the tekogane using a cutting tool. |

|

10. Once it is separated,it is hammered out to the chosen length. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 11.This is called a sunobe.At this point the blade is almost finished.It only needs to be hammered into shape. |

12.The blade is heated again and the shinogi(ridgeline),is formed by hammering. |

|

15. The finished blade |

|

|

13.The blade is filed into its final shape and clay is applied,readying the blade for the hardening process called Yaki-ire. |

|

|

|

14. Yaki-ire-quenching the blade. |

|

|

|

Back to the Kozuka kobou page |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|